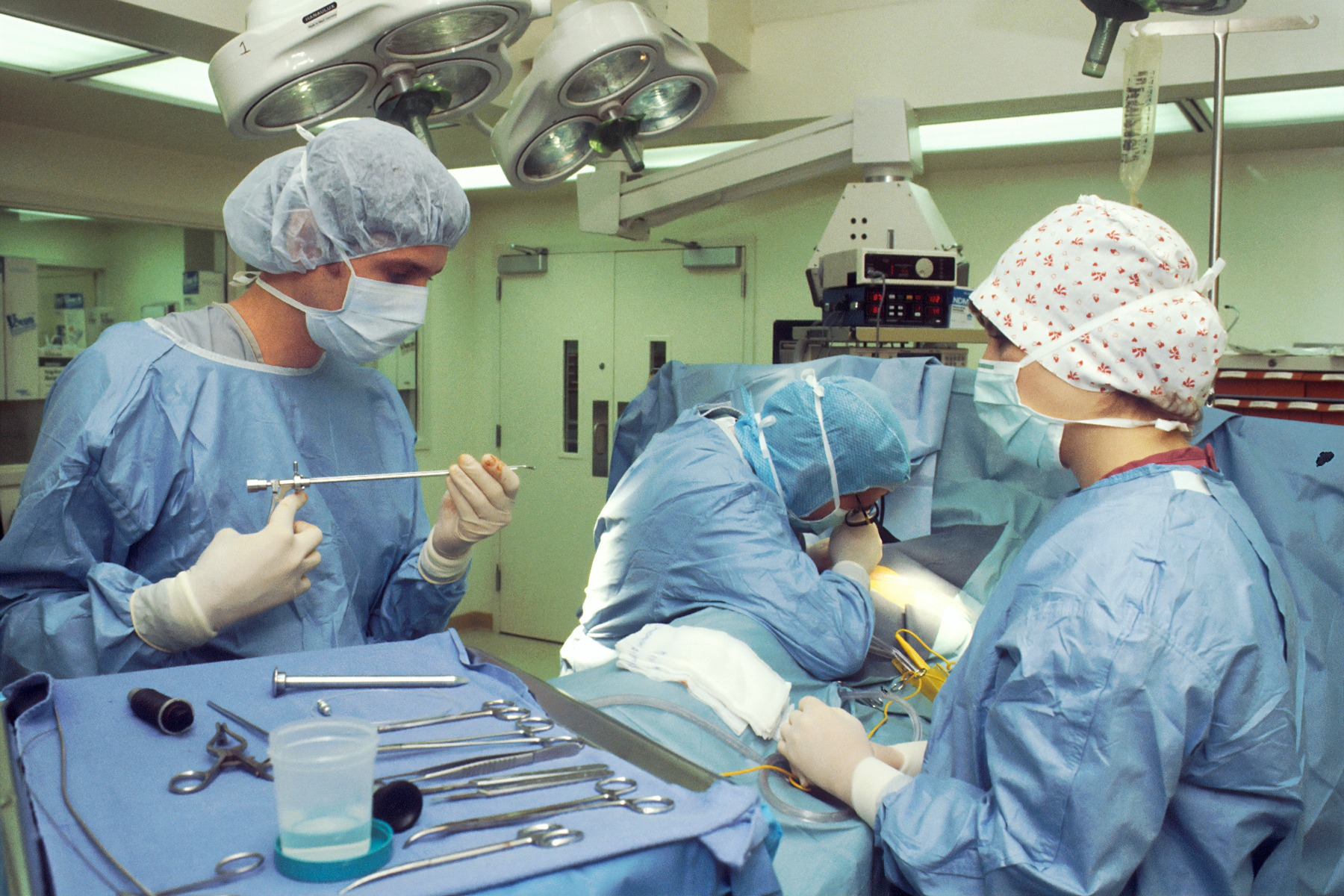

Sterile processing sits at the intersection of patient safety and operational necessity. These professionals clean, inspect, sterilize, and prepare surgical instruments that keep operating rooms running. Without them, elective surgeries get postponed, emergency procedures face delays, and infection rates climb.

The question isn't whether hospitals need sterile processing techs. They absolutely do. You need to ask yourself whether this career matches your personal goals, tolerance for behind-the-scenes work, and financial expectations. Let’s find out if it does.

The Numbers Tell a Straight and Narrow Sterile Processing Story

According to the Bureau of Labor Statistics, medical equipment preparers (which includes sterile processing technicians) is projected to grow 8% from 2022 to 2032. That equals to roughly 5,400 new positions annually.

Geographic variation matters enormously. A sterile processing tech in San Francisco pulls in around $65,000 annually, while the same role in rural Tennessee might start at $32,000. Cost of living adjustments explain some of this gap, but not all of it. Large hospital systems and surgical centers in metropolitan areas simply pay more.

The Healthcare Sterile Processing Association reports that certified technicians earn approximately 25% more than their non-certified counterparts. That certification potentially adds six figures to lifetime earnings.

Job Stability in Sterile Processing

While many healthcare segments faced furloughs and hour reductions in the past, sterile processing departments constantly work overtime.

“Without properly sterilized instruments, the entire perioperative process halts. That's job security built on fundamental necessity.”

– Terri Goodman, PhD, MPH, RN, CNOR, and FAAN

Hospitals can't perform surgery without sterilized instruments. That's not a business model that pivots with market trends. It is a physiological reality connected to human tissue and bacteria.

What the CRCST Certification Involves

The Certified Registered Central Service Technician (CRCST) credential is offered through the Healthcare Sterile Processing Association.

Health Tech Academy's Sterile Processing Program provides comprehensive CRCST certification preparation that covers everything from decontamination procedures to sterilization monitoring in just 16 weeks.

Hear from One of Our Students

The CRCST exam includes 150 multiple-choice questions covering anatomy, microbiology, surgical instrumentation, decontamination, sterilization methods, and quality assurance. You'll need to understand:

- Why steam sterilization requires specific temperature and pressure parameters.

- How bioburden affects sterilization efficacy.

- What makes orthopedic instruments different from general surgery sets.

Exam pass rates hover around 70% for first-time test-takers who complete structured preparation programs. Self-study candidates fare worse, typically in the 50-55% range. The difference comes down to understanding application – knowing why certain protocols exist.

You can assess your readiness by taking our free practice exam before committing to the full CRCST certification path.

The Day-to-Day of Sterile Processing

- You'll stand for eight-hour shifts, often longer.

- Your hands will get wet – repeatedly.

- The decontamination area smells like a combination of enzymatic detergent and biological matter.

- Temperature-controlled rooms mean you'll be cold in sterilization and warm in decontamination.

But sterile processing also comes with clear standards, measurable outcomes, and immediate feedback. Either the biological indicator comes back negative (sterilization successful) or it doesn't. Either the instrument set passes inspection, or it gets reprocessed. There's limited ambiguity.

You won't deal with patient emotions, family dynamics, or bedside manner. Some people find this refreshing. Others need human interaction to feel fulfilled in their work.

Shift work varies by facility. Large hospitals run sterile processing 24/7, meaning night and weekend shifts come with differential pay. Ambulatory surgical centers typically operate Monday through Friday, finishing by early evening. Your preference here will determine which employment settings make sense.

Career Progression Makes or Breaks Long-Term Viability

Entry-level sterile processing technicians hit a ceiling fast without upward mobility. But multiple advancement paths exist for motivated individuals.

- Lead technicians oversee daily operations, train new staff, and troubleshoot equipment problems. This role typically requires 2-3 years of experience and often comes with a $5,000-$8,000 salary increase.

- Department supervisors manage staffing, quality metrics, and regulatory compliance. They need to understand Joint Commission standards, Association for the Advancement of Medical Instrumentation (AAMI) guidelines, and hospital infection control protocols. Salaries range from $55,000 to $75,000, depending on facility size.

- Sterile processing educators train both new technicians and existing staff on updated protocols. They develop competency assessments, maintain training records, and often present at conferences. This role suits people who enjoy teaching but don't want traditional classroom settings.

- Central service managers and directors oversee entire departments, handling budgets, vendor relationships, capital equipment purchases, and strategic planning. These positions require business acumen alongside technical knowledge, with salaries reaching $80,000-$110,000 in large health systems.

Some technicians go into industry roles, working for instrument manufacturers, sterilization equipment companies, or healthcare consulting firms. These positions leverage sterile processing expertise in sales, training, or product development contexts.

The Sterile Processing Skills that Transfer

Working in sterile processing builds competencies that extend beyond healthcare. Inventory management, quality control, process optimization, regulatory compliance, and contamination control apply across industries.

Former sterile processing techs have transitioned into pharmaceutical manufacturing, laboratory management, cleanroom operations, and medical device sales. The attention to detail and protocol adherence required in sterile processing transfers well to any field that requires precision.

That said, most people in sterile processing stay in healthcare. The specialization represents both an advantage (deep expertise) and limitation (narrower application outside medical settings).

What Makes Someone Successful in this Field

If the below traits describe you, sterile processing could be your next career:

- Comfort with routine: Sterile processing involves repeated procedures with minimal deviation. If you need constant novelty, you'll struggle.

- Physical stamina: Standing, lifting instrument trays (some weighing 25+ pounds), and working in varying temperatures requires baseline fitness.

- Detail orientation without perfectionism paralysis: You need to catch a damaged instrument before it enters a surgical field, but you also need to maintain workflow. Obsessive tendencies can backfire.

- Comfort working independently: Much of the work happens without direct supervision or collaboration. If you need frequent social interaction, the isolation may wear on you.

- Respect for protocols you don't fully understand: Not everything makes intuitive sense until you've seen surgical complications from improperly processed equipment. You'll need to follow procedures before fully grasping their importance.

The Sterile Processing Regulatory Environment Gets Complex

Sterile processing techs navigate a web of overlapping standards: The Joint Commission, AAMI, Association of periOperative Registered Nurses (AORN), Centers for Disease Control and Prevention (CDC) guidelines, manufacturer instructions for use (IFUs), and state health department requirements. These don't always align perfectly.

Manufacturer IFUs might specify hand-washing for delicate instruments while automated systems would damage them, but automated systems offer better standardization. Techs need to interpret conflicting guidance and document their decision-making.

“The professional sterile processing technician does far more than clean instruments. They interpret complex IFUs, make critical decisions about reprocessing methods, and serve as the last line of defense against surgical site infections.”

– Michael Schaffer, MS, CRCST, CHL, CIS, CER, President of the International Association of Healthcare Central Service Materiel Management

This complexity creates job security but also stress. When regulatory surveyors arrive, sterile processing faces intense scrutiny. Your documentation, sterilization logs, and quality monitoring records get audited in detail.

Financial Trajectory and Expectations

With 5-10 years' experience and additional certifications (like Certified Instrument Specialist (CIS) for instrument processing or Certified Endoscope Reprocessor (CER) for endoscope reprocessing), earnings can reach $50,000-$60,000 without moving into management.

Benefits often include health insurance, retirement matching, tuition reimbursement, and paid time off. Larger hospital systems offer better benefits packages than smaller surgical centers, though the latter may provide more predictable schedules.

Overtime opportunities exist, particularly in understaffed departments or during high surgical volume periods. Some techs supplement their income by picking up per diem shifts at multiple facilities.

The financial picture becomes more favorable when considering educational investment. A CRCST certification costs substantially less than most associate degrees and can be completed in weeks rather than years. The opportunity cost stacks up enormously for career changers or those supporting families.

The Verdict

Sterile processing offers legitimate career potential for people who value stability over prestige, prefer technical precision to patient interaction, and want healthcare employment without extensive schooling.

The field won't make you wealthy, but it provides consistent work, opportunities for advancement, and skills that remain relevant regardless of technological changes. Surgical instruments will always need sterilization – even if robots perform the surgeries.

Someone with family obligations who needs immediate employment will evaluate differently than a recent high school graduate exploring options.

The certification barrier is low enough to test the waters without massive commitment. That's the value proposition: a legitimate entry point into healthcare that doesn't require years of preparation or enormous debt. Whether you stay for three years or thirty depends on what you discover once you're inside.

Frequently Asked Questions and Answers

How Long Does it Take to Become Certified in Sterile Processing?

Most candidates complete the CRCST certification within 4-8 weeks through structured programs, though some extend preparation over 3-4 months while working full-time.

Can You Work in Sterile Processing Without Certification?

Yes, though opportunities are increasingly limited. Many facilities now require certification within 6-12 months of being hired, and uncertified techs earn significantly less.

What's the Difference Between Sterile Processing and Surgical Technology?

Sterile processing techs prepare instruments before surgery and reprocess them afterward. Surgical techs work in operating rooms during procedures, handing instruments to surgeons. Completely different roles with different training requirements.

Do Sterile Processing Techs Work Directly with Patients?

Rarely. The role focuses on equipment rather than patient care, making it suitable for people who prefer technical work over interpersonal interaction.

What are the Worst Parts of the Job?

Physical demands, exposure to biological contaminants during decontamination, and repetitive tasks top the list. The lack of recognition compared to clinical roles frustrates some professionals.

Can you Make a Good Living in Sterile Processing?

"Good" is subjective. Median earnings fall below nursing and most allied health professions but above many non-healthcare occupations. Combined with lower educational barriers and strong job security, many find the trade-off worthwhile.